Pressure - Data Entry | Pipes (Oilfield)

The “Pressure” module allows the quick computation of :

- The friction and hydrostatic pressure in pipes and annulus.

- The pressure drop across a bit or a nozzle

- The injection pressure of any fluid in the formation matrix.

Moreover, different fluid models can be used to evaluate the pressure behavior of any fluid. This includes:

- Newtonian Model

- Bingham Plastic Model

- Power Law Model

- Herschel Bulkley Model

A tutorial video for data entry and calculations performed by this module is available here.

The “Pressure” Module allows the calculation of three different pipe setups being:

- Friction, hydrostatic and Injection pressures in “Pipes”

- Friction, hydrostatic and Injection pressures in an “Annular” conduit

- The pumping and circulation pressures when pumping a fluid through a pipe and then up the annulus between this pipe and another pipe or open hole.

- Newtonian Model

- Bingham Plastic Model

- Power Law Model

- Herschel Bulkley Model

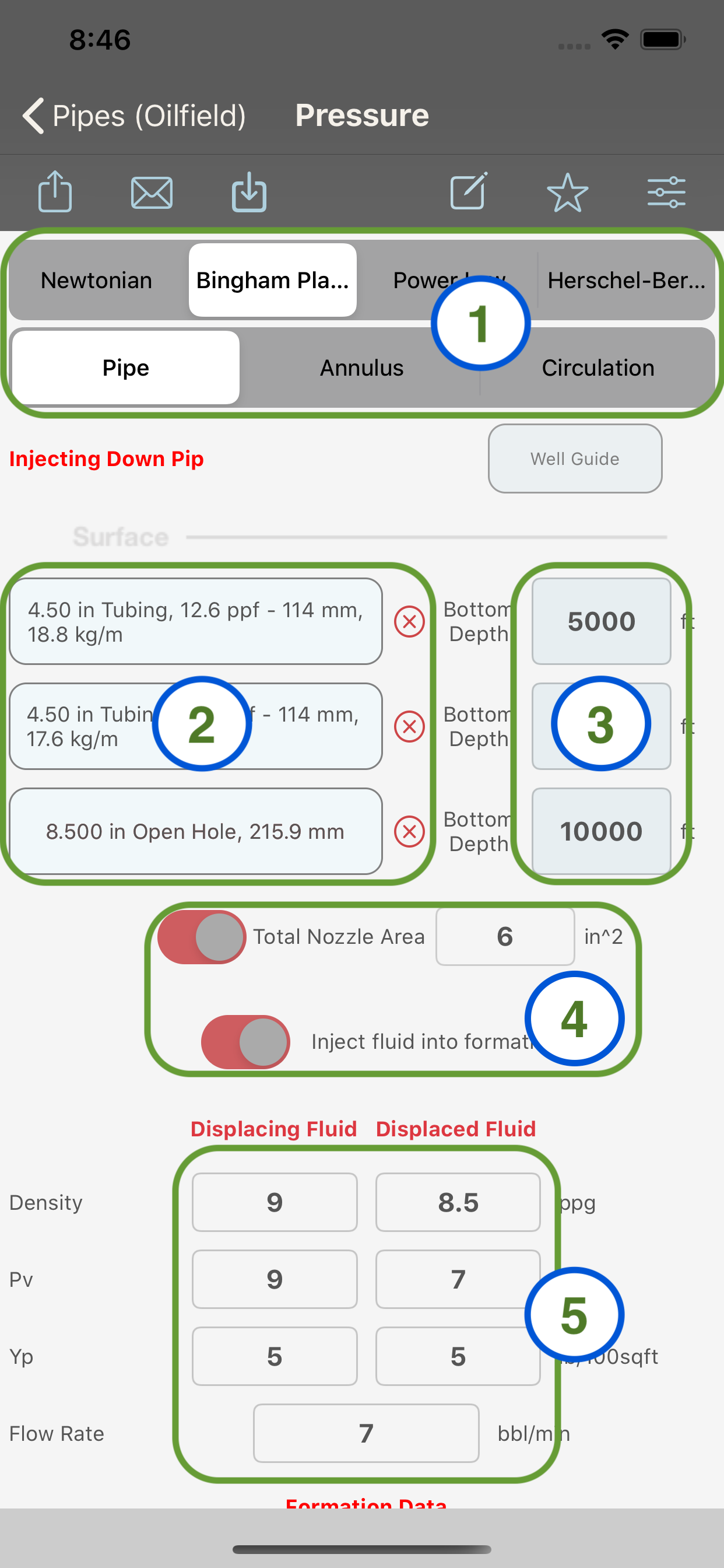

The below steps demonstrates the data sequence for any of the above calculations:

- The combination of pipe setup and fluid model are selected through the segment-controls (1)

- Then, the OD, ID, wall thickness and weight of the selected pipe can be accessed by tapping on the “Select Pipe” button (2). (please refer to “Section Selection” section of this manual).

- Enter the depths (3) against each section. These depths represent the depth of the bottom of this section and NOT the length of it.

- We can add to the string a jetting nozzle by entering its TFA in (4). The module will compute the pressure drop across the nozzle based on the fluid property and the TFA and assuming a Cd = 0.95.

- The fluids properties are entered in (5) (This section’s textfields will vary depending on the fluid model selected in (1)).

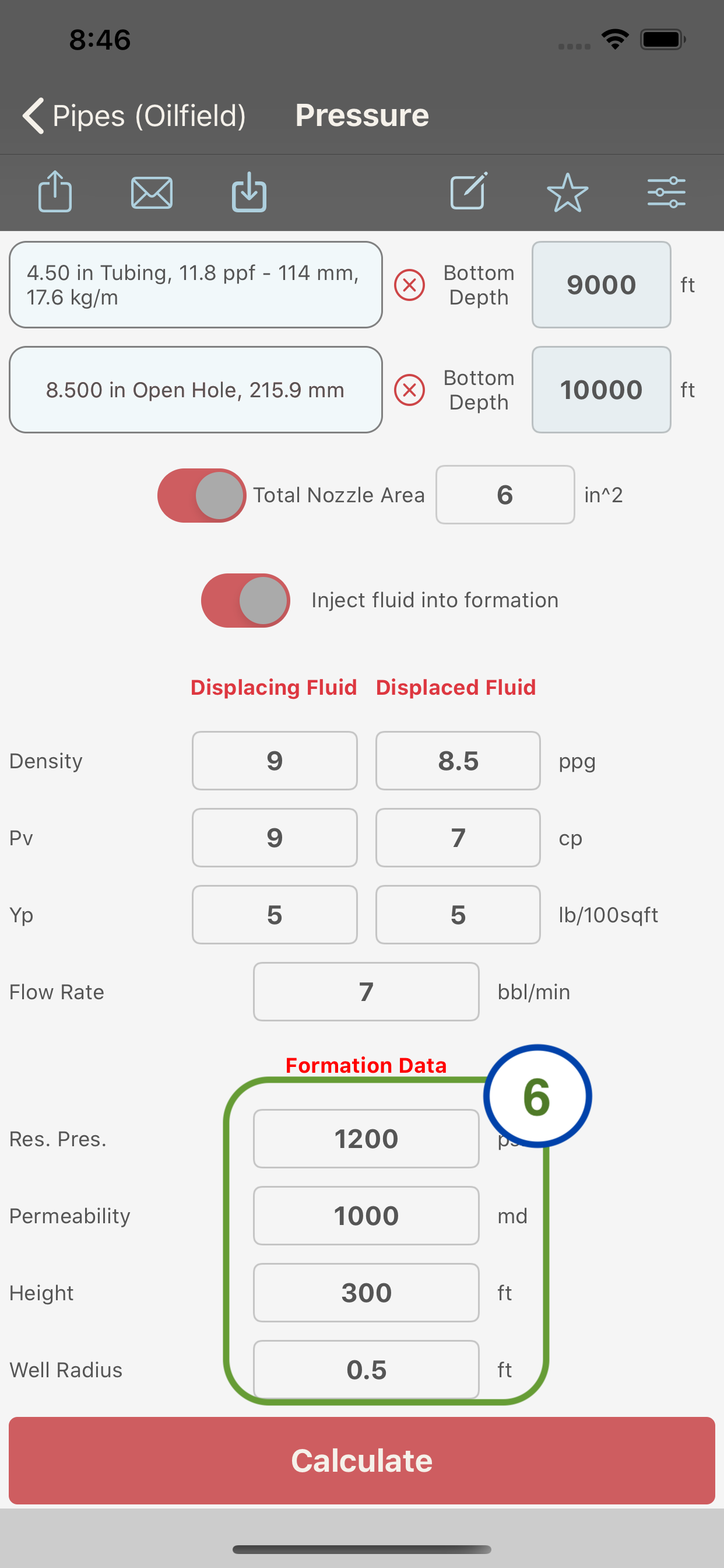

- The pumping rate used to compute the friction pressures and pressure drop across the nozzle is entered in the same section (5).

- Also, In the case of “Pipe” and “Annulus” calculation, we can calculate the injection pressure into a formation of reservoir pressure Pr, permeability k, height h and well radius r. The formation data is entered in section (6).

Note:

- When the “Annulus” calculation is selected, the nozzle pressure drop calculation is not available.

- Similarly, when the “Circulation” calculation is selected, the formation injection pressure option is not available.

Note:

- For "Annulus" and "Circulation" calculation, enter first the depths for the Outer Pipe/Hole section followed by the Inner Pipe/Hole depths

- The Pipes (Oilfield) App includes a database of all API casings, drill pipes and tubings. It also includes the most common coiled tubing and open hole sizes.

- The pipe sections are entered from top to bottom.

- Each pipe section can be of different type (casing, DP, Tubing, Coiled Tubing), sizes (OD), wall thickness and weight.

- To clear a wrong entry, tap the ⊗ buttons next to the corresponding “Select Pipe” button (2) or load from the “Select Pipe” screen a different pipe in to the section.

- User can enter up to three pipe sections in a single string (Top, Middle and Bottom pipe sections).

- It is optional to enter all three pipe/OH sections in the string i.e. only one, two or three pipe sections can be entered.

- A mix of casing, drill pipe, tubing and coiled tubing can be enter in any of the three pipe sections.

- Also, open hole sections can be added to the outer string in the case of “Annular” and “Circulation” calculations.